Workshop safety and cleanliness are paramount. In this blog post, we’ll explore how Rubber Hollow Mats contribute to maintaining safe and clean workshop floors, making them an essential addition for DIY enthusiasts and professionals alike.

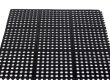

Oil and Chemical Resistance: Discuss the resistance of Rubber Hollow Mats to oil and chemicals commonly found in workshops, ensuring they maintain their functionality even in challenging environments.

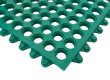

Effective Debris Containment: Highlight how these mats effectively contain dirt, sawdust, metal shavings, and other workshop debris, preventing it from spreading and creating potential hazards.

Anti-Fatigue Properties: Emphasize the anti-fatigue properties of Rubber Hollow Mats, which reduce the strain on workers’ legs and lower backs during long hours on their feet.

Moisture Management: Discuss how these mats handle moisture, ensuring that spills are quickly drained away, reducing the risk of slips and falls.

Durability in High-Traffic Areas: Mention the durability of Rubber Hollow Mats in high-traffic workshop settings, where they can withstand heavy use and remain effective for years.

Low Maintenance: Highlight the low maintenance requirements of these mats, which can be easily cleaned to maintain a safe and clean workshop environment.

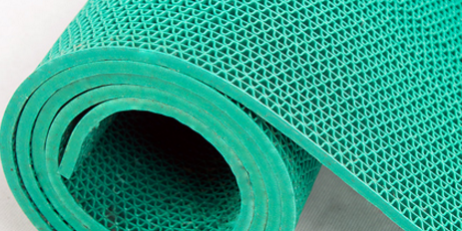

Customization Options: Discuss how these mats can be customized in terms of size and color to match the aesthetics of different workshops.

Conclusion: Rubber Hollow Mats are an indispensable addition to workshops, offering oil and chemical resistance, effective debris containment, anti-fatigue properties, moisture management, durability, low maintenance, and customization options for safer and cleaner workshop floors.